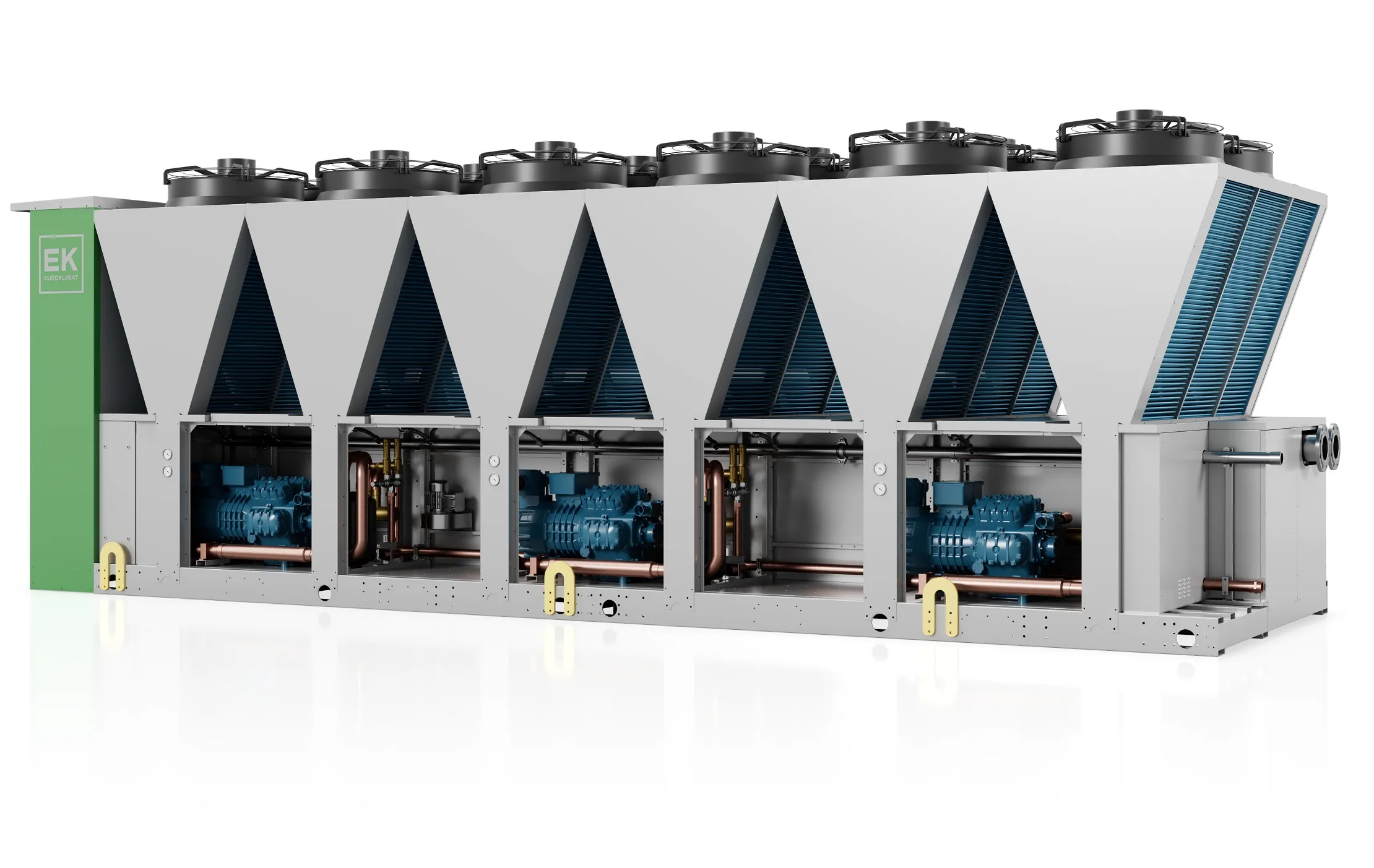

Eco-Friendly Cooling with Propane (R290)

Refcool's natural refrigerant chillers utilize the power of propane to deliver industrial cooling with virtually zero environmental impact. As businesses strive for greater sustainability, natural refrigerants have become the gold standard for green cooling solutions.

Propane occurs naturally and have no meaningful global warming effect when released, unlike synthetic F-gases. Propane (R290) has a GWP of 3 , making them exceptionally climate-friendly choices. In addition, these refrigerants do not deplete the ozone layer.

By choosing a Propane chiller from Refcool, your company demonstrates a commitment to environmental responsibility while also benefiting from the high efficiency and proven performance these refrigerants offer. Natural refrigerant chillers are an excellent long-term investment – they are immune to future phase-outs under environmental regulations, ensuring your cooling system remains viable and compliant for decades to come.

Environmental Benefits

- Zero or near-zero Global Warming Potential (GWP)

- Zero Ozone Depletion Potential (ODP)

- Naturally occurring substances, not synthetic chemicals

- Future-proof against refrigerant phase-outs and regulations

- Reduced carbon footprint for your operations

High Efficiency, Industrial-Grade Performance

Beyond their green credentials Propane chillers deliver outstanding cooling performance in industrial applications

Propane is a highly efficient refrigerant with superior thermodynamic properties, which means propane -based chillers can often achieve greater cooling capacity per unit of energy consumed compared to traditional refrigerants.

- Ideal for large-scale industrial installations

- Perfect for breweries, food processing, and cold storage

- Comprehensive safety systems for secure operation

- Robust safety systems for high-pressure operation

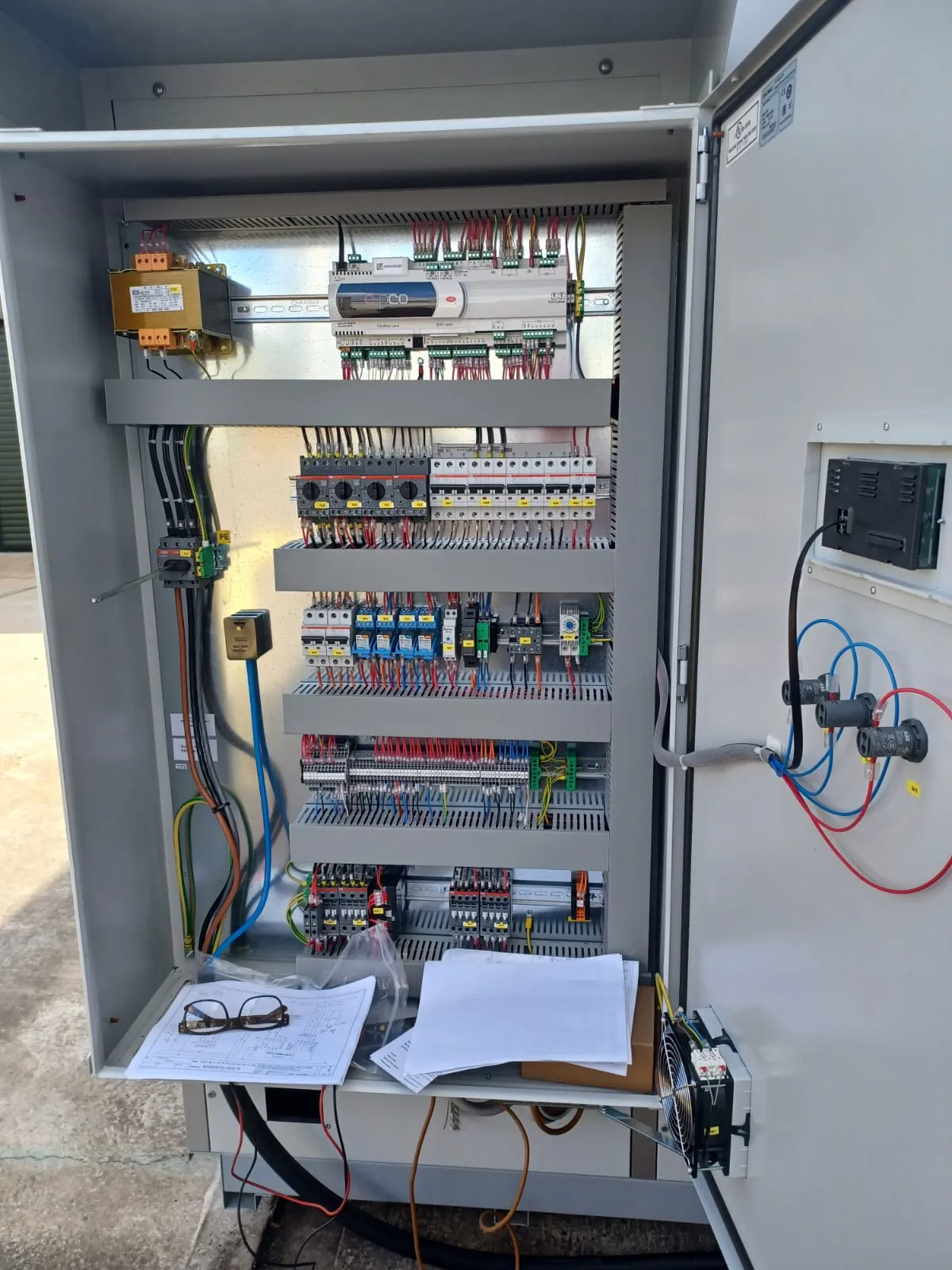

Safety and Reliability

Our natural refrigerant chillers are built with specialized components and robust safety systems, guaranteeing reliable operation and operator safety. With features like automatic leak detection, ventilation, and emergency stop mechanisms, we ensure that using Propane Chillers is as safe as it is efficient.

- Advanced leak detection systems

- Automatic ventilation and emergency protocols

- Comprehensive staff training and documentation

- Monitoring and support options

Applications and Advantages Across Industries

Natural refrigerant chiller systems from Refcool are versatile and can be tailored to a wide range of industries

Propane Chillers are often the backbone of large industrial refrigeration systems – for instance, in dairy processing or meat packing facilities, an ammonia chiller plant can provide continuous cooling for multiple production lines with incredible efficiency.

Propane Chillers are gaining popularity in commercial refrigeration (such as supermarket cold chain systems) and in data center cooling when paired in hybrid systems for higher efficiency.

Propane Chillers systems also see use in HVAC for large buildings and district cooling projects aiming to minimize environmental impact while maintaining high efficiency.

Key Advantages

Environmental Sustainability

You get stable, long-term refrigerant supply (since these substances won't be phased out) and the ability to proudly market your facility as using truly green technology.

Operational Efficiency

Potential lower operating costs due to the superior thermodynamic properties of natural refrigerants, resulting in greater energy efficiency and reduced utility bills.

Expert Support

Refcool's expertise means we handle the complexities of these systems – from proper material selection to dealing with the higher pressures.

Comprehensive Training and Support

We provide training and support to ensure your team is comfortable with the new system. Our natural refrigerant chillers offer sustainable cooling without compromise, combining the best of modern engineering with the most environmentally benign refrigerants available.

Operator Training Programs

Comprehensive training for your staff on safe operation and maintenance procedures

Technical Support

Assistance from our team of natural refrigerant specialists

Preventative Maintenance

Regular service plans to ensure optimal performance and safety

Regulatory Compliance Assistance

Help navigating the regulatory requirements for natural refrigerant systems

Get the latest cooling industry updates

Subscribe to our newsletter