Blog posts are loading

Blog posts are loading

We use the Refcool 5R Cooling Risk & Resilience Checklist with our clients to review their current cooling systems, uncover risks and strengthen operational readiness

Learn the top reasons for chiller alarms, from refrigerant leaks to electrical faults, and get tips on diagnosing and fixing common system issues.

Refcool partnered with Varian Medical to develop and service a hybrid chiller for linear accelerators (Linacs), combining traditional cooling and free cooling to provide reliable, energy-efficient cooling water for life-saving oncology equipment.

Refcool partnered with a UK UV systems manufacturer to develop specialized air-blast and water-to-water cooling units for high-power ultraviolet lamps, enabling safe, efficient operation of UV curing and drying equipment sold worldwide.

Refcool replaced an obsolete coil-in-tank oil cooler on a key machine tool with a custom 2.5 kW single-phase chiller and pump system, maintaining 20 °C oil temperature and improving the tool’s uptime and efficiency.

Refcool delivered a full cooling system for a new plastics injection molding facility – designing a twin-circuit pipework network, integrating new chillers and dry coolers with existing equipment, and commissioning the system on a tight timeline.

Learn how Refcool engineered a compact, high-capacity cooling unit (the i-ACE system) for a server cabinet manufacturer, enabling direct cooling of high-density server racks in confined spaces without sacrificing maintenance access.

Refcool delivered two custom cooling projects: a multi-circuit skid for a plasma power system with raw/deionized water and gas distribution, and dual pump skids for an international furnace operation, each designed for reliability and easy maintenance.

Refcool replaced a large 350 kW central chiller with a modern multi-scroll unit featuring advanced controls and free-cooling integration, cutting energy use at part load and improving system dependability for the client.

Refcool implemented a turnkey gas dewatering system – using a glycol chiller and specialized heat exchanger – at an anaerobic digestion plant to remove moisture from biogas, improving burn efficiency and reducing engine maintenance.

Refcool implemented a full turnkey cooling installation – including dual parallel chillers and custom pressure controls – for a medical scanner service center, ensuring reliable climate control of sensitive equipment.

Refcool supplied a custom 64 kW dual-circuit, low-noise chiller to replace a failing MRI cooling unit in a harsh coastal environment, ensuring uninterrupted, quiet cooling for critical medical equipment.

Discover how Refcool replaced an aging 108kW central chiller with the UK’s first modular unit of its kind – a high-efficiency system with capacity for future expansion, completed on time and on budget.

Refcool designed a custom twin-chiller cooling skid with backup capacity and precision temperature control for a life sciences application, ensuring reliable, high-quality process cooling.

A plastics manufacturing facility partnered with Refcool to replace aging cooling systems with a custom propane chiller solution, cutting energy use and near-eliminating refrigerant emissions.

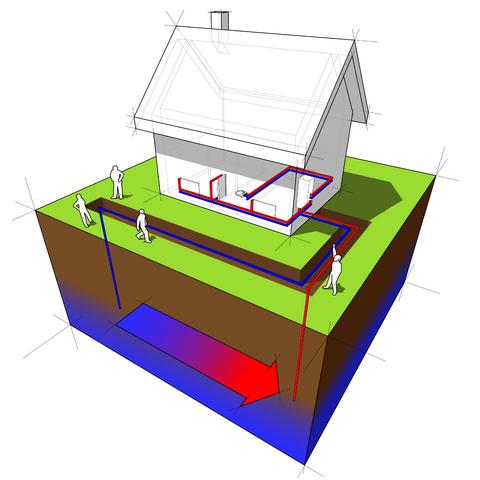

Refcool's open-loop ground source heat pump system provides sustainable heating and cooling for a facility, significantly lowering energy costs and carbon emissions.